Schematic of an experimental setup for nanoindentation on AAO-Al composite foils.

Load against depth for ex situ and in situ nanoindentation. (For more detailed explanations, please view the published article)

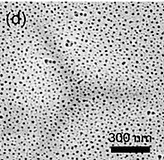

SEM images of nanoidented sample without undergoing actuation

SEM images of nanoidented sample that underwent actuation showing plastically deformed enlarged pore mouths

Nanoporous anodized aluminum oxide actuator

Synthesis: The actuator is a bi-layer nanoporous anodic aluminum oxide (AAO)/bulk Al. The actuator was fabricated from a Al foil -- one side of the foil was covered by insulating lacquer while the other side was left exposed to anodize in 0.3 M H2C2O4 to obtain a nanoporous structure.

Actuation mechanism: The resulting nanoporous structure and actuation mechanism are both highly similar to that of nanoporous gold (NPG). When nanoporous AAO is positively charged in an electrolyte, negative ions are attracted to the metal's surface (also known as "space-charge" region) and repels the free electrons within the AAO's surface layers. This results in weaker interatomic bonds at the surface and a decrease in surface compression, allowing the bulk to expand [2]. However, different from NPG where all surface areas are potential sites for storage of ionic charges, the ions are mainly attracted to the "bottom of the pores" in nanoporous AAO actuator. This phenomenon is due to a unique "Cabrera-Mott potential barrier" which occurs at the oxide/metal interfaces, close to the bottom of the pores, where the electric field intensity is much higher than other locations in the oxide. Hence, the main expansion in the actuator takes place at the bottom of the pores.

Performance: The 1 inch- long cantilever nanoporous AAO actuator exhibited reversible free end-displacement of ~ 25.5µm observed under optical microscope when a step voltage of 20V was periodically switched on/off. Each actuation took place within 2 seconds after the voltage had been switched on.

Nanoidentation was carried out on the AAO sample while it was still undergoing anodization process. Interesting enough, by comparing the indentation depth of the indenter with and without connecting voltage to the sample, a 500 nm actuation displacement (= maximum depth of indenter while voltage was off (ex situ) - minimum indenter depth while the voltage was on (in situ)) was already identified at the stage of synthesis (see figure below). Moreover, the actuation amplitude was stable at different time points of anodization (see bottom right figure, blue and black lines, ex situ conditions). This is because increased oxide (AAO) thickness would not significantly change the metal/oxide surface area, where the actuation mostly take place.

Expansion of U-shaped pore channels during actuation

Background:

It is well known that relatively cheaper metals such as Al and Ti can be anodized to form a layer of nanoporous oxide with similar microstructure as nanoporous gold. During anodization of metal, pore channels in the oxides grow vertically towards the metal substrate, resulting in a highly hierarchical structure that is different from the disordered nanoligaments in de-alloyed nanoporous metals. In addition, it is known that the pore size and porous pattern can be conveniently controlled by the anodization conditions.

Summary: Although the present strain is not comparable to most nanoporous metals, a fast actuation response was observed in this actuator. The actuator is synthesized from nonprecious metal with a low cost anodization approach, which distinguishes itself from existing nanoporous Au/Pt actuator synthesized from de-alloying method. We have also identified an actuation phenomenom where the actuation takes place mainly at the bottom of the pores, which has not been reported before.

References:

[1] Cheng C, Ngan AHW. 2013. Charge-induced reversible bending in nanoporous alumina-aluminum composite. Appl. Phys. Lett. 102, 213119-1:4

[2] Detsi E, Tolbert SH, Punzhin S, Jeff De Hosson TM. 2016. Metallic muscles and beyond: nanofoams at work. J. Mater. Sci., 51:615 - 634, 2016.

The actuation mechanism of nanoporous AAO is confirmed by SEM images taken after the nanoidentation experiments. When nanoporous AAO is indented during actuation, the enlarged pore mouths would be plastically deformed. The pore mouths could not recover to its original shape even if the voltage has been switched off, and would thus leave a trace at the sample's surface. If AAO actuator had not been actuated during nanoindentation, enlarged pore holes will not show in the indented region (see figures below).